Carbon-Based Nanomaterials

Inorganic Chemistry Programme, Department of Materials Chemistry, Uppsala University

Contact: Ulf Jansson

www.mkem.uu.se

Our work focuses on the synthesis and characterization of new nanostructured carbon materials. The research covers a broad spectrum from materials design, synthesis and characterization. The principal synthesis method is magnetron sputtering and the group is strongly dependent on the access to materials analysis using e.g. XPS, SEM, nanoindentation, electrical characterization. We are also when need using additional deposition equipment available at MSL. Three examples of current research projects are:

Nanocomposites

Carbide-based nanocomposites have interesting chemical and physical properties and a large potential in e.g. low-friction coatings and electric contacts. The films typically consist of nanocrystalline carbide grains in an amorphous matrix. The properties are strongly dependent on the carbide and matrix structure and in some applications the matrix must be tuned to a thickness of 1-2 monolayers. This can be achieved by “designed alloying” where metastable solid solutions are formed during the sputtering process. The final properties of the films are dependent on the chemical properties of the alloying elements. We are currently studying a large number of different systems such as Ti-Ni-C, Ti-Fe-C, Nb-Si-C, Zr-Si-C and W-M-S-C (M=Ti, Cr..)

Metal Carbide Glasses

The magnetron sputtering process occurs far from equilibrium and the rapid quenching of the impinging atoms makes it possible to form amorphous materials. For metal carbides these materials can be considered as metallic glasses similar to those obtained in rapid solidification of melts. We are currently running a project trying to identify growth mechanisms and film properties for such glasses. This involves improved understanding of the sputtering process, advanced materials analysis (TEM, XPS, EELS and EXAFS) as well as theoretical modelling in co-operation with groups at the Physics Department.

Combinatorial Materials Science

We are currently starting a larger project on combinatorial materials science in co-operation with groups at the Department of Physics and the Department of Engineering Sciences. The aim with this project is to screen a large number of materials systems using sputtering equipment which can deposit the entire phase diagram in e.g. a ternary system in a single experiment. The films are then rapidly characterized using analysis methods dedicated for rapid materials analysis. Initially, this approach will be used to identify new nanocomposites and carbide glass systems.

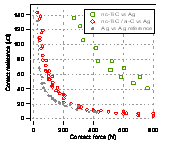

TEM cross section of (left panel) nc-(Ti1-xNix)C/a-C nanocomposites with amorphous matrix coloured in blue and (middle panel) a metal carbide glass of Zr-Si-C. The right panel shows the contact resistance of a nc-TiC/a-C film compared to a Ag contact. Note that the nanocomposites and Ag have similar contact resistances, suggesting a potential use of these materials in electric contacts.